How to increase the amount of slag materials processing in Ukraine

The roundtable to find answers to this question was held on June 27, 2019 at the Ministry of Ecology and Natural Resources of Ukraine.

The urgency of the issue determines the critical situation. Currently, Ukraine has about 35-36 billion tons of accumulated waste. In terms of area, it occupies 7% of the country's territory, more than 50 thousand tons per km2. The amount of accumulated waste dumps from TPP is more than 244 million tons, metallurgical slag - more than 100 million tons. In addition to the already accumulated slag are added those that are constantly formed in the technological process of production. In the next 3-5 years, a significant number of man-made waste dumps will be overcrowded and exhausted.

Even though all operators comply with the norms, man-made waste becomes a source of dust pollution, poses a danger to the health of people, flora and fauna of the surrounding areas (mobile elements are actively washed out by precipitation, polluting the air, water and soil).

Waste or materials?

At the beginning of the meeting, attention was paid to the fact that the current regulatory framework clearly sets out the conditions for classifying slag materials as waste or as a product (raw material). The manufacturer, who complies with the specifications, considers the slag materials as a product. For this purpose it is necessary to carry out appropriate tests and develop the manufacturer's quality passport.

Recycling Solutions: opportunities for the use of slag materials in Ukraine

Schauenburg Maschinen-und Anlagen-Bau GmbH: slag dehydration of coal-fired power plants

In chemical and mineralogical composition, slag materials are largely identical to natural mineral raw materials. They belong to the 4th class of safety and the 1st class of radiation safety (i.e. they are safe). The current regulatory framework (DSTU, DBN) allows them to be used in the production of building materials or as materials for construction.

Possible ways of using slag materials as substitutes for natural mineral materials for construction

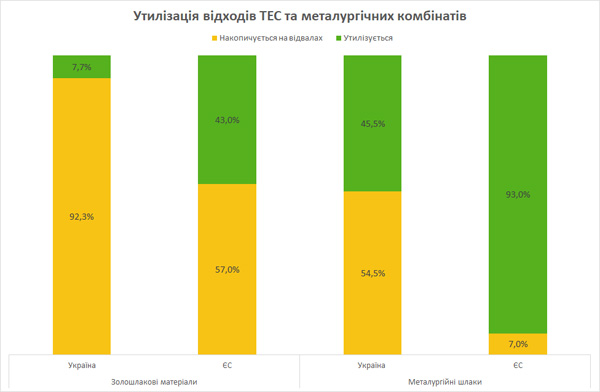

At the same time, Ukraine does not significantly reach the global indicators, in particular the EU indicators, in the use of slag materials in construction, agriculture, etc.

Such state of affairs indicates that:

1) Man-made waste as a resource is undervalued by the Ukrainian economy;

2) There are no effective environmental and economic instruments in the field of waste management in the country, which should stimulate their recycling in order to be used as raw material or the material used instead of natural exhaustive resources;

3) The lack of inter-sectoral cooperation in waste management issues, both at the authorities and business level, makes it impossible in practice to prioritize resource conservation and implement the measures.

The representatives of the following organizations took part in the discussion: the Ministry of Ecology and Natural Resources, the Ministry of Infrastructure, the Metallurgical Federation of Ukraine, Ukrmetallurgprom, the All-Ukrainian Union of Manufacturers of Building Materials, the Association "Ukrcement", the Confederation of Builders of Ukraine, leading energy generating companies (Energoatom, Metinvest, Arcelor Mittal Kryby Rih, and others), the Association of Cement Manufacturers of Ukraine, Ukravtodor, Ukrzaliznytsia, scientific, expert and public organizations.

What prevents to increase the use of slag?

The participants of the meeting noted the following problematic issues in the process of increasing the use of slag materials in construction:

1) Low index of development of construction and as a consequence, low capacity of the market of building materials and products for which slag materials can be used;

2) Logistics problems and transportation costs, which make the cost of slag materials for the end consumer higher than the cost of natural mineral materials on the "short logistics shoulder";

3) Need to review the outdated regulatory framework and carry out studies of the physical and chemical parameters of slag materials in accredited laboratories;

4) Absence of a state order for constructing objects with the use of lag materials;

5) Lack of implemented state aid instruments for economic entities for capital investments in the most up-to-date technologies that will ensure the use of slag materials in the production of building materials and construction.

Comments of the participants

Andriy Glushchenko, Candidate of Economic Sciences, GMK Center analyst

“Slag is profitable to use in Ukraine. For public authorities, slag recycling means reducing the environmental footprint and improving the quality of the roads. For local governments - improving the ecological situation and reclamation of land from landfills. For cement mills, the use of slag is to reduce CO2 emissions and energy costs. For road builders - increasing road resistance to loads. In turn, for metallurgical and energy-generating enterprises, there is no need to look for new lands for slag removal, and in addition, slag is a source of raw materials and an additional source of income.”

What are the opportunities to increase the use of slag in Ukraine?

Ivan Saliy, President of the All-Ukrainian Union of Building Materials Manufacturers

“Concretes, paving stones, bricks, dry mixes, heaters, fillers, cement have significant potential for environmental and economic feasibility. But in order to increase the use of slag materials in construction, it is necessary to increase the volume of construction work. Construction in our country should grow 3-5 times! The volume of construction in Ukraine makes 3.2 billion EUR per year, in Turkey - 130 billion EUR, in Poland - 48 billion EUR. We should reach the level of development in Poland not in 50, but in 3-5 years.”

Development of construction industry in Ukraine

Roman Filonenko, Head of Environmental Safety at the Division of Waste Management and Environmental Safety, Department of Environmental Safety, Permitting and Licensing of the Ministry of Ecology and Natural Resources of Ukraine

“The Ministry of Ecology and Natural Resources of Ukraine is consistently working to reform the legislation in the field of waste management. The Decree of the Cabinet of Ministers of Ukraine # 820-p of 08.11.2017 approved the National Waste Management Strategy 2030, which defines the general measures in the field of waste management in general and special measures in the field of management of individual types of waste. The Decree of the Cabinet of Ministers of Ukraine # 117-p of February 20, 2019 approved the National Waste Management Plan 2030. According to the requirements of the mentioned acts of the Government, during 2020 it is envisaged to develop (governmental and local authorities) and approve in a prescribed order (Ministry of Environment, Ministry of Regional Development) the drafts regional waste management plans. They are the key to building a waste management system across the country with the involvement of municipalities, businesses and investors. The Ministry is currently developing methodological recommendations for the development of regional plans. We look forward to proposals, in particular on the implementation of pilot projects on the construction of transport structures using slag materials. We are planning to develop sectoral waste management laws and we are open to cooperation in this area. "

Olexandr Bondar, Rector of the State Ecological Academy of Postgraduate Education and Management

“First of all, we need the state support measures aimed at supporting the enterprises specializing in the processing of industrial waste. The Academy has the appropriate staffing and scientific capacity to participate in the establishment and maintenance of a proper national waste management system. This should be one of the priorities of the state policy, despite the limited resource and economic capacity of the country."

Svetlana Lapovska, Doctor of Technical Sciences, Deputy Director for Scientific Work of the Ukrainian Research Institute of Building Materials and Products

«Asphalt roads are most common in Ukraine. In their construction, it is possible to use fractionated slag as a large and small aggregate (instead of granite rubble). You can also replace mineral powder from natural limestone with ground slag. The existing regulatory framework allows the use of slag in virtually any layer of road clothing. The studies have shown that up to 35% of slag in the coating layer, up to 50% in the base layer, up to 10% in the ground layer and up to 30% for roadside can be used for the construction of asphalt concrete roads. However, we should not limit ourselves to the construction of roads. We are looking for new ways of using slag, in particular, to produce different types of concrete."

As a result of the meeting, the recommendations for the draft National Environmental Action Plan 2020-2025 were approved.

The Proposals to the National Action Plan for the Implementation of the State Environmental Policy Strategy 2020-2025.

1. Legally approve the minimum quantitative indicator (percentages, share, etc.) of the obligation to use slag materials in their fields of application in the implementation of specific projects; review and amend sectoral development programs accordingly, setting targets for the use of slag materials.

2. Provide for the implementation of pilot projects for the construction of transport structures and other facilities using slag materials when developing regional waste management plans. The implementation of the project should involve the study of the object in operation and an assessment of its condition under the influence of various factors.

3. Review and, if necessary, amend the normative documents (DBN, DSTU) on the use of slag materials in the production of building materials and in the construction (repair) of transport structures and other objects of construction (carry out if necessary additional studies or tests). In particular, ensure the revision of the following:

- ДСТУ Б В. 2.7.-35 Crushed stone, sand and gravel-sand mixture of blast furnace and steel slag for civil engineering works. Specifications

- ДБН В.2.3-19-2018 Transport structures. Track gauge 1,520 mm. Design rules

- СОУ 42.1-37641918-104-2013 Ash-drifts and mixtures of ash-slag from thermal power plants for road works

4. Develop national standards (ДСТУ) for environmental impact assessment for transport facilities and other construction sites, taking into account requirements for the use of slag materials.

5. Establish by the act of law a list of recommended criteria for technical specifications for contractors of repair and construction works in order to meet the needs of the state and the territorial community, in which to determine the minimum quantitative indicator of the use of slag materials.

6. Consider the feasibility of increasing the rent for the special use of natural mineral resources (sand, gravel, etc.), which can be replaced in the construction by slag materials.

7. Ensure the reform of the environmental tax with a view to its full use for environmental measures (creation of special fund) and reduction of the taxpayers in the reporting tax period the amount of environmental tax directed at capital investments in the most modern technologies, in particular, such that will ensure the use of slag materials in production and construction materials.

8. Provide state support for capital investments in state-of-the-art technologies in the criteria for assessing the admissibility of state aid to environmental protection entities, which will ensure the use of slag materials in the production of construction materials and construction.

9. Consider the following:

9.1 Keep the procedure for determining the tariffs for the carriage of goods by rail by classes of freight.

9.2 Partial compensation for freight traffic at the expense of the carrier's environmental tax.

9.3 Preferential tariff for the carriage of goods by rail at the expense of budgetary expenses for the implementation of environmental measures.

10. Ensure cross-sectoral engagement and exchange of information on this issue with the stakeholder involvement, in particular when discussing the proposals submitted.

Svitlana Berzina, President of the NGO Living Planet, chair of the Public Council at the Ministry of Ecology and Natural Resourses

“There are technological solutions and successful projects for the use of slag materials in construction. It is proved that these materials are better for building on physical and chemical properties than natural minerals. They improve the quality of construction sites and increase their lifecycle. Besides, it is important for the conservation of natural exhaustive resources and the reduction of polluted areas under industrial waste. We have prepared the recommendations to the authorities, such as encouraging the use through government procurement. But political will and real action are needed. We hope that our proposals will be adopted in a national action plan aimed at implementing the updated state environmental policy approved by the Law this year. It is also a challenge to the political forces that are going to participate and win elections to the Verkhovna Rada of Ukraine.”

Non-price criteria for road repairs and construction works

The examples of successful use of man-made wastes to replace natural mineral materials in construction in Ukraine and in the world.

The Ukrainian manufacturers of building materials consume 96% of ash and slag materials of the total recycling volume, which is 7.7%. Fly ash is used for the production of concrete, bricks, insulation mixtures, cement, slag blocks, aerated concrete, abrasives, foam concrete, roofing material, dry construction mixtures, paving slabs and slate.

The Kovalska Industrial Construction Group has been using dry fly ash for the production of commercial concrete, dry mixes, reinforced concrete products and tiles for over 4 years. More than 70% of Kyiv facilities are constructed using high quality Kovalska Concrete. The main consumers of metallurgical slag in Ukraine today are cement producers: CRH, Dickerhof Cement Ukraine, Heidelberg Cement Ukraine, Ivano-Frankivsk Cement, etc.

In the cement industry, almost 42% of metallurgical slag is utilized out of a total utilization rate of 45.5%.

20% of metallurgical slag is used in road construction. In particular, such highways as Mariupol-Zaporozhia, Zaporozhia-Dnipro, Dnipro-Kryvy Rih and roads H-31 (P-52) Dnipro - Tsarichanka - Kobelyaky - Reshetilivka were constructed using blast furnace slag.

Steelmaking slug is practically useless, whereas in the EU, according to EUROSLAG, 46% of its total utilization is for road construction. It is also used in the EU as a mineral fertilizer (2.7%) and for hydraulic engineering (2.2%).In Ukraine, 19% of metallurgical slag goes to oblivion of mined space in the mining and metallurgical industries. In recent years, manufacturers of mineral wool have become interested in metallurgical slag.

Instead of cement: the use of slag in Ukraine

Arcelor Mittal Kryvy Rih (AMKR) proposes to build concrete roads from metallurgical waste

Bogdan Rublyuk: "The use of slag allows to save on cement"

Ukraine can five times increase the use of slag in road construction

Benefiting: how the Europeans make money on slag

5 examples of the use of slag in US construction

Emirates Steel has signed a ten-year contract for slag processing

Thank you for your information support and photos: